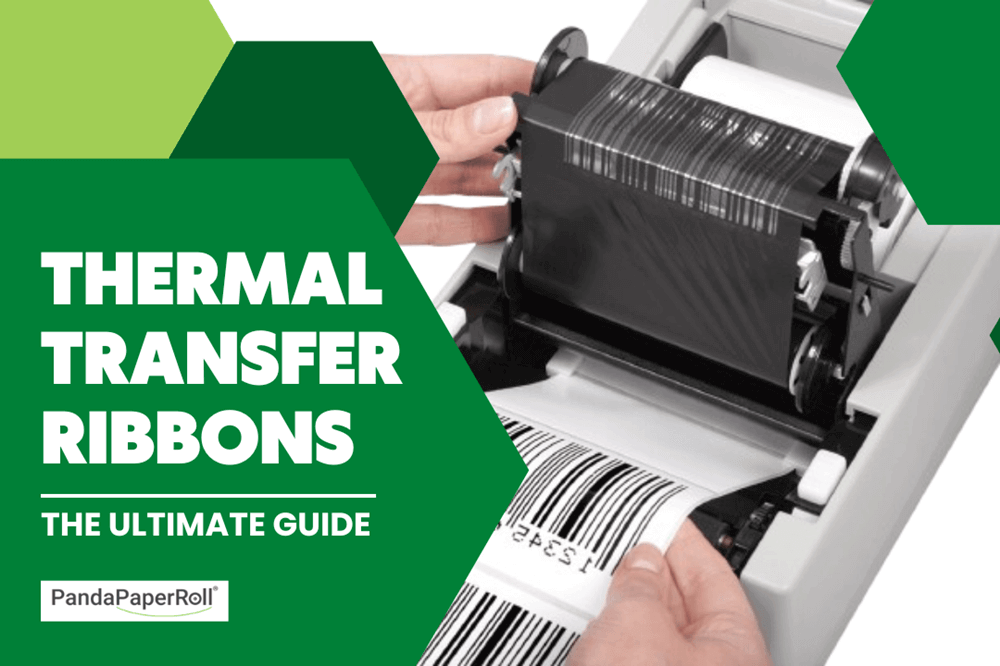

If you’re here, this means you’re curious about barcode clarity and print longevity, and more specifically – Thermal Transfer Ribbons. Do you find yourself lost in the terminology of wax, resin, or wax-resin ribbons? Unsure which type suits your printing needs? Fear not! We’re here with the best guide to thermal transfer ribbons, answering your questions and guiding you through the various aspects of this special kind of ribbons.

From price tags on clothing, barcodes on grocery items, or labels on laboratory samples, trust me, thermal transfer ribbons are everywhere!

So, if you’re curious to know more about these tiny superheroes of the printing world, stick around.

The reason why we have brought you the full info on how they work, the different types available, and the advantages and disadvantages, is to educate you on the best way to choose the right kind based on your specific needs.

Without any fluff, let’s get straight into it, starting with the understanding of what are these ribbons, exactly.

What is a Thermal Transfer Ribbon?

Thermal transfer ribbon, often simply referred to as ‘ribbon’, is a critical part of thermal printing. These ribbons find extensive use in various industries and deliver optimal print quality depending on the ribbon type used.

A thermal transfer ribbon is a component used in thermal transfer printers to print your desired images or barcodes on the material – usually thermal transfer labels. With help from a thermal printhead, the printer precisely melts the wax or resin from the ribbon onto the label surface, to create a durable print.

These ribbons play a crucial role in ensuring high-quality, durable prints for labeling and barcoding applications across various industries such as manufacturing, logistics, healthcare, retail, and more.

Choosing the right type of ribbon for your specific application is essential in achieving the desired print quality and longevity of the labels.

But before going to that part, you need to educate yourself about some important aspects until you can make the decision the right one.

This is why let’s get a good understanding of how the structure of a transfer ribbon looks and behaves.

The Structure (Different Layers) of Transfer Ribbon

Every thermal transfer ribbon consists of four layers – a ribbon black layer, a wax or resin layer, a base film layer, and the back coating.

While the black layer provides color, the wax or resin forms the characters or barcode upon melting. The base film offers support, and finally, the back coating protects the printhead.

To understand the construction and application of each layer, have a look at this brief listing:

- Ribbon Black Layer: This layer is made of a pigmented material that provides the color for the printed images or text. It is responsible for the visual representation of the printed content on the label or substrate.

- Wax or Resin Layer: The wax or resin layer is the functional layer of the ribbon that contains the ink which melts and transfers onto the label or substrate when heat is applied. This layer is crucial for creating high-resolution, durable images and text.

- Base Film Layer: This layer serves as the foundation of the thermal transfer ribbon, providing support and stability to the other layers. It is typically made of polyester or similar materials and is essential for maintaining the integrity of the ribbon during printing and handling.

- Back Coating: The back coating is a protective layer applied to the underside of the ribbon. It serves to protect the printhead of the thermal transfer printer from damage caused by friction, heat, or debris during the printing process. This layer also helps to prolong the life of the printhead and ensure consistent print quality.

While the three mentioned types are the primary categories of thermal transfer ribbons, there are also variations within these types, catering to specific needs. Some additional considerations are:

- Color Ribbons: Vibrant prints, perfect for colorful labels.

- Near-Edge Ribbons: High-speed precision for efficient printing.

- Textile Ribbons: Durable prints for fabric labels.

Each of these layers plays a critical role in the functionality and performance of the thermal transfer ribbon, working together to produce high-quality, long-lasting printed labels and images.

Types of Thermal Transfer Ribbon

Now, it’s time to discuss the types of thermal transfer ribbons in the industry that you can utilize when it comes to customizing your own ribbons for the best thermal label.

Whether you’re navigating the cost-effective landscape of wax ribbons, seeking the balance of wax resin, or requiring the uncompromising durability of resin ribbons, each type serves a distinct purpose.

Here are the 3 main types of ribbons available in the market:

1. Wax Ribbons

Wax ribbons use a standard wax base, best suited for paper material due to their lower smudge resistance. They are made of wax-based ink that is transferred onto paper or other materials through the use of heat, usually from a thermal transfer printer.

They are perfect for general use and offer the lowest price of thermal ribbons.

To be more specific, they are used for printing barcodes, labels, and other types of high-volume printing applications. The wax-based ink used in these ribbons provides a durable and long-lasting print, making them ideal for industrial and commercial uses.

2. Wax-Resin (Hybrid) Ribbons

A wax resin ribbon is a premium blend of wax and resin, ensuring a harder print than wax thermal ribbons. It offers better resistance to smearing, ideal for semi-gloss paper and some synthetic materials.

Wax-resin ribbons, also known as hybrid ribbons, are a type of thermal transfer ribbon used in barcode and label printing. They are a combination of wax and resin materials, which makes them more durable and resistant to wear and tear compared to standard wax ribbons.

This makes them suitable for applications that require more durable and long-lasting labels, such as outdoor labeling, shipping and logistics, and even asset tracking.

3. Resin Ribbons

Resin thermal transfer ribbons, often referred to as ‘durable resin’, make use of a full resin formulation. They are designed for extreme environments and are most resistant to smudging and scratching.

These ribbons are made of a special type of ink, which is a resin-based material that has a high degree of durability and resistance to harsh environmental conditions. These ribbons are characterized by their composition, which includes a higher percentage of resin compared to wax or wax-resin ribbons.

Resin ribbons are designed for use in applications where labels need to be able to withstand exposure to extreme temperatures, chemicals, and abrasion. This makes them ideal for use in industries such as healthcare, automotive, and manufacturing, where labels need to remain readable even in challenging conditions.

Here is A Table Comparison for the 3 Types of Ribbons

| Type | Wax Ribbons | Wax-Resin (Hybrid) Ribbons | Resin Ribbons |

|---|---|---|---|

| Material | Standard paper labels | Semi-gloss paper labels and certain synthetic materials | Polyester (PET), Polypropylene (PP), and Polyethylene (PE) |

| Features | Cost-effective solution for standard paper labels with good print quality. | Balanced option providing durability for semi-gloss paper and synthetic materials. | Highest durability, ideal for synthetic materials, with resistance to harsh conditions and high-resolution printing. |

| Application | Retail, Logistics, and Inventory management. | Product labeling, Healthcare, and Asset tracking. | Pharmaceuticals, Chemicals, and Outdoor Asset Tracking. |

| Suitable Labels | Product labels, Shipping labels, and Retail tags. | Retail tags, Product labels, and Inventory management. | Chemical drum labels, Outdoor Asset tags, and labels in Pharmaceutical and Industrial settings. |

What Is CSO And CSI?

Coated Side In (CSO) and Coated Side Out (CSO) are two terms explaining the orientation of the coating that is done on a thermal transfer ribbon. For instance, Zebra printers often use CSO-oriented ribbons and cater to a broad range of industrial thermal transfer applications.

CSO means that the coated side of the ribbon faces outwards, away from the label or material being printed on. This means that the ink is transferred from the ribbon onto the label as it passes through the printer.

On the other hand, CSI means that the coated side of the ribbon faces inwards, towards the label or material being printed on. Here the ink is transferred from the ribbon onto the label as it comes into contact with the ribbon inside the printer.

It’s important to use the correct ribbon orientation for your specific printer and application to ensure the best print quality and durability. So, make sure you get clear info on these “little things” while checking the thermal rolls or transfer ribbons for yourself.

Where Are Thermal Transfer Ribbons Used For?

From shipping labels to clothing tags, thermal transfer ribbons are used in various domains. Industries such as retail, hospitality, logistics, the health sector, and more make use of thermal transfer ribbons for reliable barcode printing, maintaining organization, and inventory control.

Thermal transfer ribbons are commonly used for printing labels and tags for products, packaging, and shipping. They are also utilized in industries such as manufacturing, automotive, pharmaceuticals, and food and beverage for printing information such as batch numbers, expiration dates, and product identification.

These are used in the healthcare sector for printing wristbands, patient identification labels, and specimen labels.

Advantages And Disadvantages Of Thermal Transfer Ribbons

Thermal transfer ribbons excel in durability, high-quality print, color range, and versatility across various materials. They’re superior compared to direct thermal printing. However, they are also a bit pricier than the latter and require a ribbon change after some use.

Hence, when it comes to the advantages and disadvantages of thermal transfer ribbons, you need to understand both of them before you go for the right one when you’re choosing one of these.

Also, the reason why we have presented you with all of these points, structures, types, uses, etc., aspects of thermal transfer ribbons so that you can recognize the best one for your needs.

5 Powerful Advantages of Thermal Transfer Ribbons

- Durability: Thermal transfer ribbons produce long-lasting, durable prints that are resistant to fading, smudging, and scratching.

- High-quality print: They offer sharp and clear prints with high resolution and precise details.

- Color range: Thermal transfer ribbons come in a wide range of colors, allowing for vibrant and customizable printing.

- Versatility: They can be used on various materials, including paper, film, foil, and synthetic materials.

- Superior to direct thermal printing: Thermal transfer ribbons provide better print quality and durability compared to direct thermal printing.

4 Main Disadvantages of Thermal Transfer Ribbons

- Price: Thermal transfer ribbons are generally more expensive than direct thermal printing supplies, making them a costlier option for printing needs.

- Ribbon change: They require the ribbon to be changed after a certain amount of use, adding to the cost and maintenance of the printing process.

- Set-up and maintenance: Using thermal transfer ribbons may require additional set-up and maintenance compared to direct thermal printing, as the ribbon and printer settings need to be properly calibrated.

- Print speed: Thermal transfer printing can be slower compared to direct thermal printing, which may not be suitable for high-volume printing needs.

You can consider the different disadvantages and see what works for you and against you here. For some people quality and durability are the most important, while for some price is the top priority.

And with whatever suits best for you, it will help you understand the perfect material that fits your goals.

Now, without any ado, let me take you to the final part of this article, where you’ll get the cream of the article. After educating yourself on all the various types, structures, benefits, disadvantages, and stuff, you need to understand the factors to consider while choosing the right transfer ribbon for you or your business.

Tips To Choose The Best Quality Thermal Transfer Ribbons

When choosing thermal ribbons, consider your printing needs, substrate material, and the environmental conditions the labels will be exposed to. The best thermal transfer ribbon for you is ultimately one that delivers exceptional print quality at a suitable price.

Here are some tips to help you choose the best quality thermal transfer ribbons:

- Understand your printing needs: Consider the type of label you will be printing, such as barcode labels, shipping labels, or product labels. Different applications may require different ribbon formulations to ensure optimal print quality and durability.

- Consider the substrate material: The substrate material, such as paper, synthetic materials, or films, can impact the choice of thermal transfer ribbon. Some ribbons are designed specifically for certain types of substrates to ensure adhesion and durability.

- Evaluate environmental conditions: If the labels will be exposed to harsh environmental conditions such as extreme temperatures, moisture, or chemicals, it is important to choose a ribbon that can withstand these conditions to ensure the longevity of the printed labels.

- Quality of print: Look for thermal transfer ribbons that offer high-quality, sharp, and durable printouts. The ribbon should ensure that the printed labels are clear, easy to read, and can withstand environmental factors without smudging, fading, or smearing.

- Compatibility with printer: Make sure the thermal transfer ribbon is compatible with your printer model. Some ribbons are specifically designed for certain types of printers, so it’s important to check compatibility before making a purchase.

- Cost-effectiveness: While it’s important to choose a high-quality thermal transfer ribbon, it’s also important to consider the cost. Look for a ribbon that offers a good balance between quality and price, ensuring that you are getting the best value for your money.

- Supplier reputation: Choose a reputable supplier who offers a wide range of thermal transfer ribbons and provides excellent customer support and technical assistance. A reliable supplier can help you choose the right ribbon for your specific needs and provide ongoing support as needed.

Hence, considering these factors and doing thorough research (which you don’t even need to consider when you come to us), you can choose the best quality thermal transfer ribbons that meet your specific printing needs and deliver exceptional print quality at a suitable price.

FAQs:

1. Are there only black thermal transfer ribbons?

No, there are also colored thermal transfer ribbons available in addition to black.

2. What are the common thermal transfer ribbon problems?

Some common problems with thermal transfer ribbons include wrinkles, wrinkles on the ribbon, poor print quality, and ribbon jams.

3. Can thermal transfer ribbons be used with any printer?

Thermal transfer ribbons are compatible with thermal transfer printers specifically designed to accommodate ribbon rolls, ensuring optimal printing performance. Some common problems with thermal transfer ribbons include wrinkles, wrinkles on the ribbon, poor print quality, and ribbon jams.

4. How do you properly store and handle thermal transfer ribbons?

To properly store and handle thermal transfer ribbons, it’s important to keep them in a cool, dry environment and avoid exposing them to direct sunlight, excessive heat, or moisture. Proper handling also involves using clean gloves to avoid oil and dirt transfer onto the ribbon.

Conclusion

Therefore, these thermal transfer ribbons play a vital role in the printing industry, and choosing the right type of ribbon is crucial for achieving high-quality prints. Understanding the different types of ribbons, their components, and their applications can help businesses make informed decisions when it comes to selecting the right ribbon for their printing needs.

With the right knowledge and resources, businesses can ensure that their thermal printers are equipped with premium-quality ribbons that deliver excellent results. Need to connect with experts for more information or to source premium high-quality ribbons for your thermal printers? Don’t hesitate to contact us, we’ll be happy to assist.

How often do they need to be replaced?