Labels, in partnership with label printers, are indispensable assets across industries, from businesses to warehouse management and logistics. In this article, we will walk you through the basic knowledge about label printers and label materials, and crucially, methods for measuring label sizes. Reading these will help you better understand how this small peel-and-stick stuff contributes to organizational efficiency and productivity in the modern world.

Label Printers

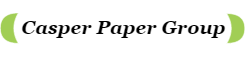

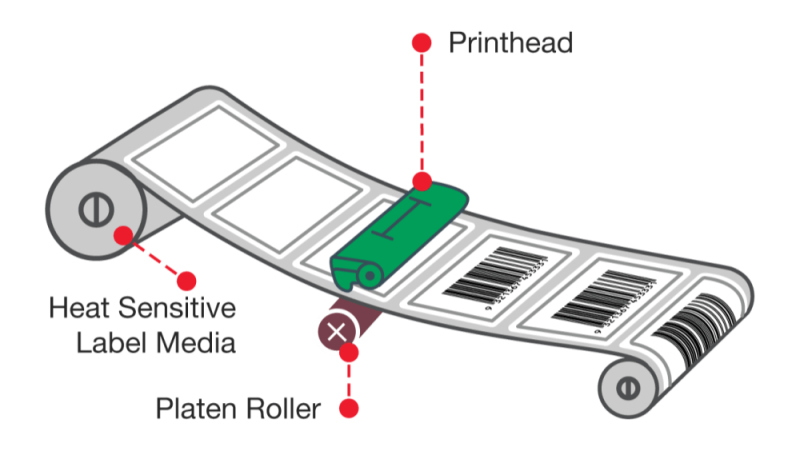

The production of large volumes of labels and customized labels can be eased by using a label printer, which, as a bonus, is cost-effective. The label printers come in different sizes and prices and use a common technology known as direct thermal printing and thermal transfer printing. Some label printers are designed for fast and bulk printing, while others are designed for detailed and high-definition prints. How well a label printer prints is highly dependent on the type of label roll being used, the best label printers will still not print accurately and clearly if the type of label roll used is of very low quality.

Generally, purchasing a label printer comes hand in hand with purchasing labels, as they are considered to complement each other.

Labels

Labels, or self-adhesive labels, are simply the materials printed by the label printer. Labels come in specific sizes, generally measured in width and height, since label printers are designed in different sizes. So, there is a specifically sized label for a type of label printer. Also, the variety of label printers depends on the printing technology of the label printer and the application of the label.

The selection of good labels will depend on the label printer specification, the size of the labels, the required durability of the labels, the color of the material, and your budget. Generally, labels are usually made of paper or plastic composite materials; other materials may include foils, films, thermal stock, and adhesive.

Types of Labels

There are several types of label rolls, and they are classified according to the printing technology used, the end-use application, and the type of label printer. Here is a list of general types of labels:

- Direct thermal labels

- Thermal transfer labels

- Laser labels

- Tags

- RFID labels

- Freezer labels

The Two Main Types of Labels You Should Know

The two main types of labels are:

How to Measure A Label Roll Size?

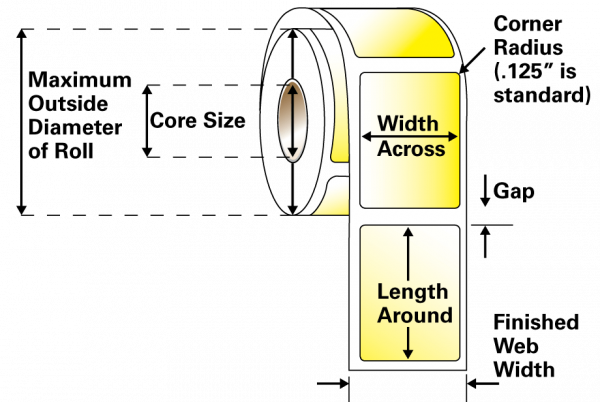

Measuring a label roll size involves several key dimensions, which will be explained below in detail:

- Label width: or “width across”, it refers to the width of a single label. It is critical for printer compatibility.

- Label length: or “length around”, it refers to the height of a single label.

- Finished web width: It refers to the full label width (a label width plus the spaces on two sides).

- Gap: The gap is the space between each label. It is usually 2mm or 3mm.

- Corner radius: It refers to the radius of a label. The standard corner radius is 0.125” (3mm).

- Core size: Generally, the core is the tube on which the labels are wrapped. The size of the core varies and depends on the label printer, but the regular core sizes are 1″ (25mm), 1.5″ (38mm), and 3″ (76mm).

- Label roll diameter: It refers to the diameter of the whole label roll while still wrapped on the core.

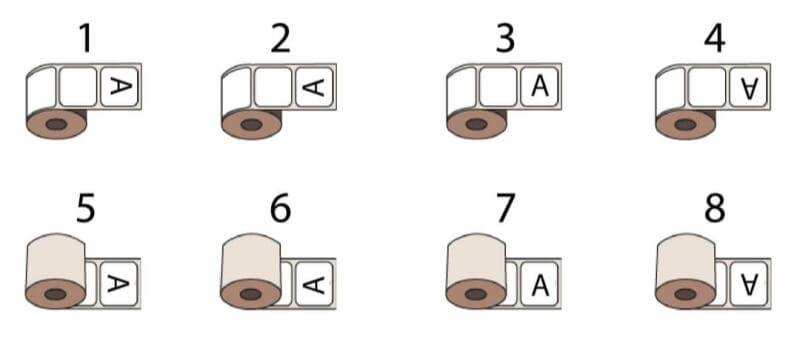

- Winding Direction: It refers to the way that your labels are oriented on the roll when you unwind it.

Summing Up

Now that you’re equipped with the basics of label printers, label materials, and label size measurement, the possibilities are endless! As you embark on your labeling journey, remember the importance of choosing high-quality label rolls to ensure reliability and durability in your printing tasks. For premium label rolls that meet your needs, consider purchasing from our company, Panda Paper Roll. With our commitment to excellence and customer satisfaction, we provide top-notch products that empower you to achieve your labeling goals with confidence. Please do not hesitate to contact us to share your label roll details and requirements and ask for a quote from us.