Ultrasound thermal print paper is a special print media with a coating of materials that changes color when subjected to heat. The heat-sensitive materials – dyes and developers, are mixed with other materials and applied evenly across the paper. When this paper is subjected to heat from a thermal printer head, it will melt (even so slightly), become discolored, and print the selected input on the paper.

Thermal papers can be used in various thermal printing equipment, and an ultrasound thermal printer is one of several applications. It is usually built with a couple of material layers, and they add different properties to the final product.

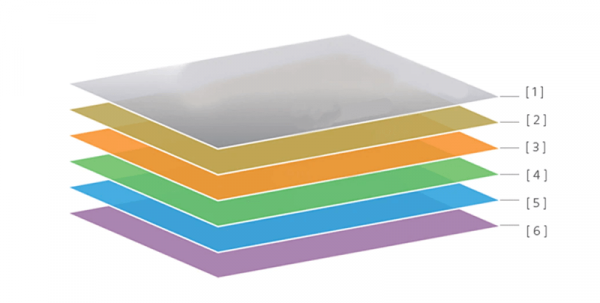

Ultrasound Thermal Print Paper Structure

[1] High gloss [2] Protective coat 2 [3] Protective coat 1 [4] Thermal coat [5] Synthetic paper (base material) [6] Back coat Source: Sony website

The first layer is the base layer and is made to be glossy. Subsequent layers might include a couple of protective layers that secure it against heat and make it more smooth and uniform. These layers are followed by the thermal layer that contains the print materials. The last layers protect the thermal layer, with the backcoat being one of those that serve this purpose.

How does Ultrasound Thermal Paper Work?

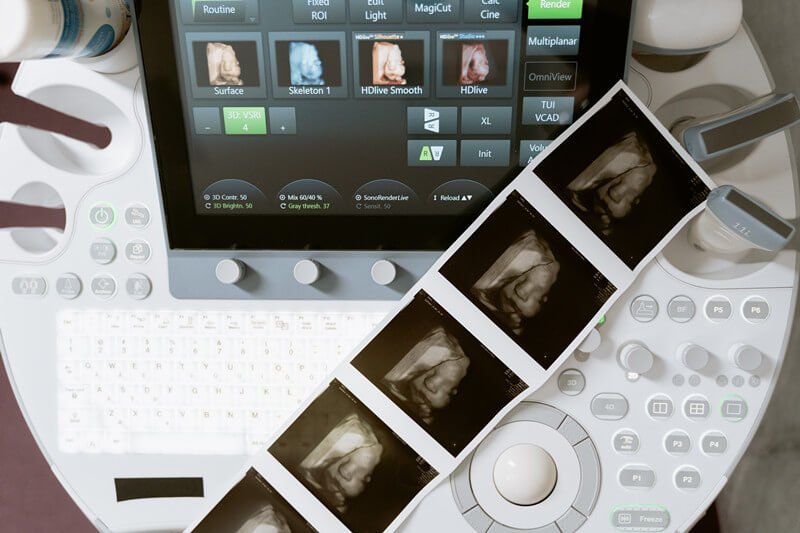

During an ultrasound procedure, the ultrasound machine generates images by sending high-frequency sound waves into the body. These sound waves bounce off tissues and organs inside the body, creating echoes. The ultrasound machine captures these echoes and converts them into electrical signals. These signals are then processed and used to generate images of the internal structures.

To print these images on thermal paper, the ultrasound machine sends the processed image (digital) data to a thermal printer. The heating elements in the printer head then activate the special dye in the thermal paper, producing gray and black shades that translate to the images. These images appear in grayscale, with different shades corresponding to the image data received from the ultrasound machine, which can reflect different states of the captured body parts. Typically, the darker the shade, the stronger the original echo from the ultrasound.

How are Ultrasound Thermal Paper Rolls Made?

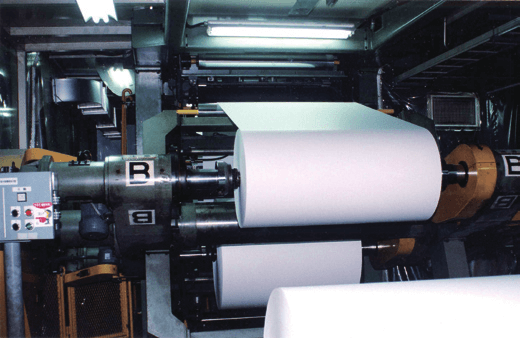

Thermal paper coating process

The first step is called “coating” or “thermal coating”. In a giant industrial coating machine, the normal paper would be coated & produced on a massive scale using large molds and massive amounts of mixing synthetic & chemical materials. They would then be built into jumbo rolls before they can be cut down to the desired sizes, then we can cut the jumbo rolls into the small finished rolls as per the customer’s requirement. For more details, you can refer to this article on our website to learn more about how thermal paper rolls are cut.

The cutting process can be repeated to produce rolls of different sizes according to customer demand. After that, the rolls can then be secured against humidity and sunshine by packing them in waterproof pouches.

What Are the Typical Paper Sizes?

The following are some typical ultrasound paper roll sizes:

| Width | Model | Size |

|---|---|---|

| A7 Width | UPP-84HG | 84mm x 12.5m |

| A7 Width | UPP-84S | 84mm x 13.5m |

| A6 Width | UPP-110HG | 110mm x 18m |

| A6 Width | UPP-110HD | 110mm x 20m |

| A6 Width | UPP-110S | 110mm x 20m |

| A4 Width | UPP-210HD | 210mm x 25m |

| A4 Width | UPP-210SE | 210mm x 25m |

While this is not a complete list, it includes some of the most widely used paper sizes for ultrasound machines. Any of the sizes listed above can be used in an ultrasound machine as long as it fits properly into the printer’s paper slot. Before anyone can use it, the thermal paper must be rolled to the correct diameter and inserted into the ultrasound printer. It then works by rolling across a heated printer head with all the heating elements.

Storage Conditions

High Gloss Ultrasound Paper Roll Source: Panda Paper Roll

The unused thermal paper should be rolled into the right diameter and stacked against each other inside a carton. You can store the carton in a dark place, and the storage site should preferably have a room temperature below 30°c.

At temperatures above this mark, the prevailing heat could be just enough to cause the materials in the paper to react. It should also be prevented from contacting materials like oils, grease, and body fluids.

In cases where the thermal paper has been printed on, its storage conditions become even more delicate. The following instructions should be adhered to maintain the quality of the image.

- Storage locations should have temperatures below 30°c and relative humidity below 60%.

- The surface of the printed paper should not be placed in petrol or any other organic solvent.

- It should be secured against contact with direct sunlight or any other light source.

- It should be stored in cases or files made with polyester.

- It should not come in contact with human bodily fluids.

In Conclusion

Due to the nature of their material makeup, ultrasound thermal papers are very valuable to the work of medical professionals. They are used to print out photographs of internal organs and body parts, and the pictures are then used to make important medical inferences. But before they slot into the printers in an ultrasound machine, they go through a series of processes that give it form and function. This article discusses these processes and then suggests storage conditions that can help attain the product’s shelf life. If you want to buy high-quality and affordable ultrasound thermal rolls, please feel free to contact our company.

Can I used to print uv ink on theremal paper