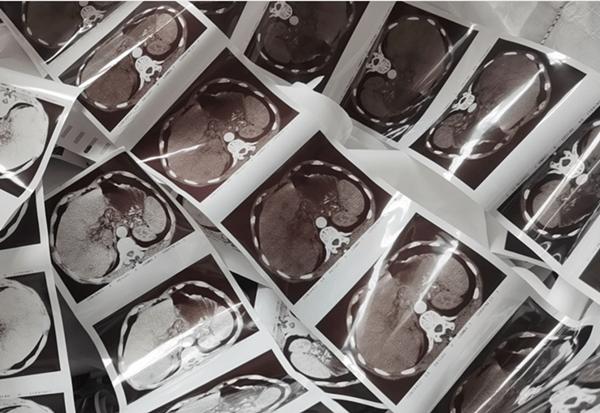

When it comes to ultrasound imaging, the quality of the images you get is just as important as the machine itself. That’s where ultrasound thermal paper comes in. This special paper works with ultrasound machines to create clear, detailed prints that doctors rely on to diagnose a wide range of conditions. The sharper and more accurate the image, the easier it is for healthcare professionals to analyze and interpret the information they need.

Choosing the best ultrasound thermal paper can be challenging for healthcare professionals and procurement managers alike, but don’t worry! This article will introduce the top 5 factors to consider when choosing the right paper for your healthcare facility.

1. Image Quality and Resolution

Ultrasound thermal paper greyscale gradation Source: Panda Paper Roll

Image quality encompasses clarity, sharpness, and accuracy, ensuring fidelity and intricate detail in the printed image on thermal paper. Resolution, on the other hand, is determined by the number of pixels or dots per inch (DPI) and directly impacts the level of detail in the image. The higher the resolution, the more nuanced and detailed the image becomes.

When searching for thermal print paper, be meticulously particular about image contrast. This ensures clear visualization of anatomical structures and abnormalities. Look for thermal papers that offer sharpness and detail. It allows you to capture even the subtlest nuances in ultrasound images. With superior grayscale reproduction, there can be an accurate representation of varying tissue densities in medical imaging.

2. Paper Durability and Longevity

Durability refers to the ability of the paper to withstand wear, tear, and damage from external factors such as moisture and heat. Longevity, on the other hand, pertains to the lifespan of the paper in terms of its ability to maintain its quality and clarity over time. Both durability and longevity directly impact the quality of images produced by the ultrasound machine.

Ultrasound thermal paper is made from synthetic materials, which offer a smooth and uniform surface for printing, resulting in enhanced image quality. They are specifically designed with high gloss and printability to ensure excellent resolution of ultrasound images.

To safeguard the quality of printed images, it is essential to store the thermal paper under appropriate conditions. Ultrasound thermal paper should be stored in a cool, dry environment to prevent moisture absorption, which can lead to image distortion, smudging, or paper deterioration. Excessive humidity or exposure to direct sunlight should be avoided, as they can compromise the paper’s performance and cause discoloration.

Additionally, it is recommended to store the thermal paper away from chemicals, solvents, and substances that emit strong odors. These can potentially react with the paper’s coating, affecting image quality and durability.

Consider using archival-quality storage solutions, such as acid-free envelopes or boxes, to protect the ultrasound thermal print paper from external elements. These solutions offer added protection against yellowing, fading, and physical damage, preserving the printouts for an extended period.

3. Compatibility with Ultrasound Machines

Ultrasound machines come in different brands, models, and specifications, thus, each one has its own specific requirements for thermal paper sizes and grades. These can significantly impact the quality and reliability of printed ultrasound images.

Begin by consulting the ultrasound machine’s user manual or contacting the manufacturer to identify the recommended thermal paper types and specifications. Pay attention to details such as paper size, sensitivity, and recommended printing settings. Adhering to these guidelines ensures optimal performance and compatibility between the ultrasound machine and thermal print paper.

By selecting thermal print paper compatible with your ultrasound machine’s specifications and printing method, you can optimize image quality, prevent printing errors, and enhance the overall efficiency of your diagnostic workflow.

4. Cost-effectiveness

Panda Paper Roll’s high gloss thermal paper Source: Panda Paper Roll

Cost-effectiveness isn’t just about finding the lowest price out there. It’s about getting the best value for your money. That means you need to look at more than just the price tag. Consider the quality of the paper, how much you’ll be using, and how often you’ll be restocking.

Here are some facts for you to chew on. Some cheaper thermal papers may be thinner and have less coating, meaning they won’t last as long. You’ll end up having to replace them more often, and that can add up over time. If you’re using a lot of thermal paper, you’ll want to ensure you’re getting a bulk discount on large volume orders.

But don’t just go for the most expensive option either. Sometimes you’re paying for a fancy brand name or unnecessary features that you don’t really need. You’ll want to make sure you’re getting a good balance of quality and cost, which brings us to the last point.

5. Supplier Reputation

Panda Paper Roll’s thermal paper print result Source: Panda Paper Roll

It may seem like a no-brainer, but this factor is extremely important when purchasing top-quality thermal paper. You don’t want to be stuck with a supplier that has a bad reputation because this can lead to inconsistent paper quality and other customer service issues.

To ensure you choose a reputable ultrasound thermal paper supplier, do some research. Check out online reviews and customer feedback to see what other medical professionals say about the supplier. You can also ask colleagues in the industry for their recommendations. Don’t be afraid to ask questions and inquire about their manufacturing process and quality control measures.

Additionally, some thermal paper manufacturers offer warranties or guarantees on their products. These assurances provide peace of mind and protection against potential defects or subpar performance. Consider the value of these warranties when assessing the cost-effectiveness of different thermal paper options.

Conclusion

Choosing the best ultrasound thermal print paper is an important decision that directly affects the accuracy of diagnostic imaging and the longevity of medical records. With over 20 years of experience in supplying thousands of healthcare companies and organizations worldwide, we understand how important it is to find long-term business relationships that also deliver exceptional products.

To ensure excellent image quality, durability, and compatibility with different ultrasound machines, Panda Paper Roll offers a wide range of high-quality ultrasound thermal paper options. Our acid-free and lignin-free papers are designed to withstand the test of time, providing you with reliable and long-lasting medical records. We would be happy to assist you in exploring our comprehensive range of thermal paper solutions.